Skip to Content

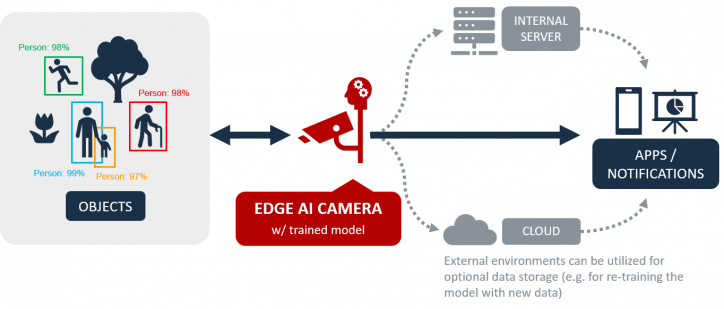

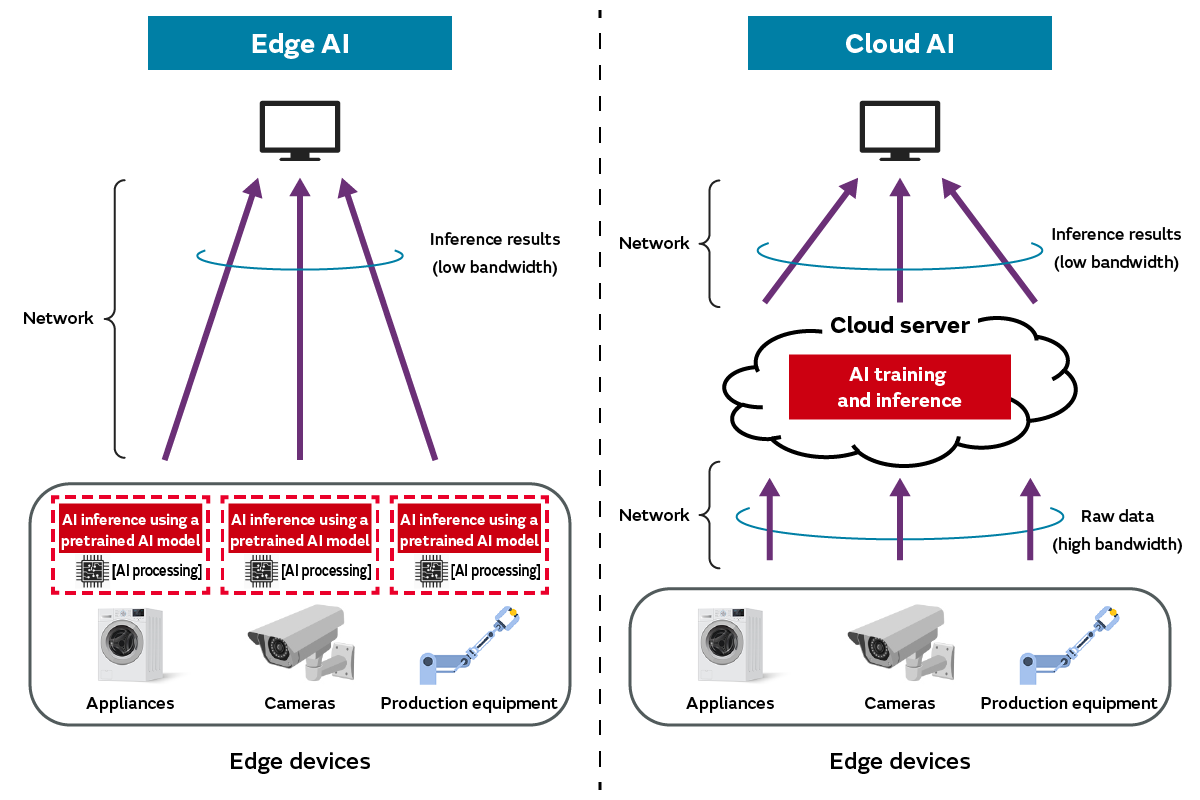

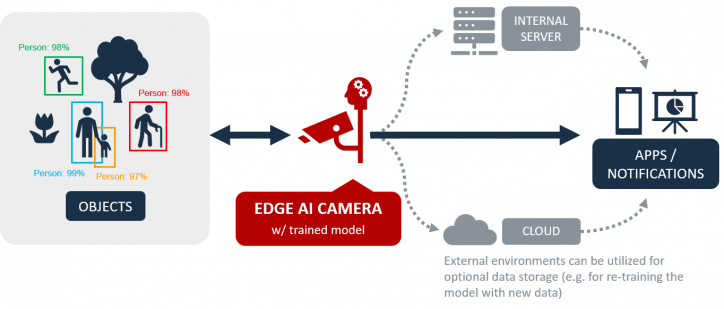

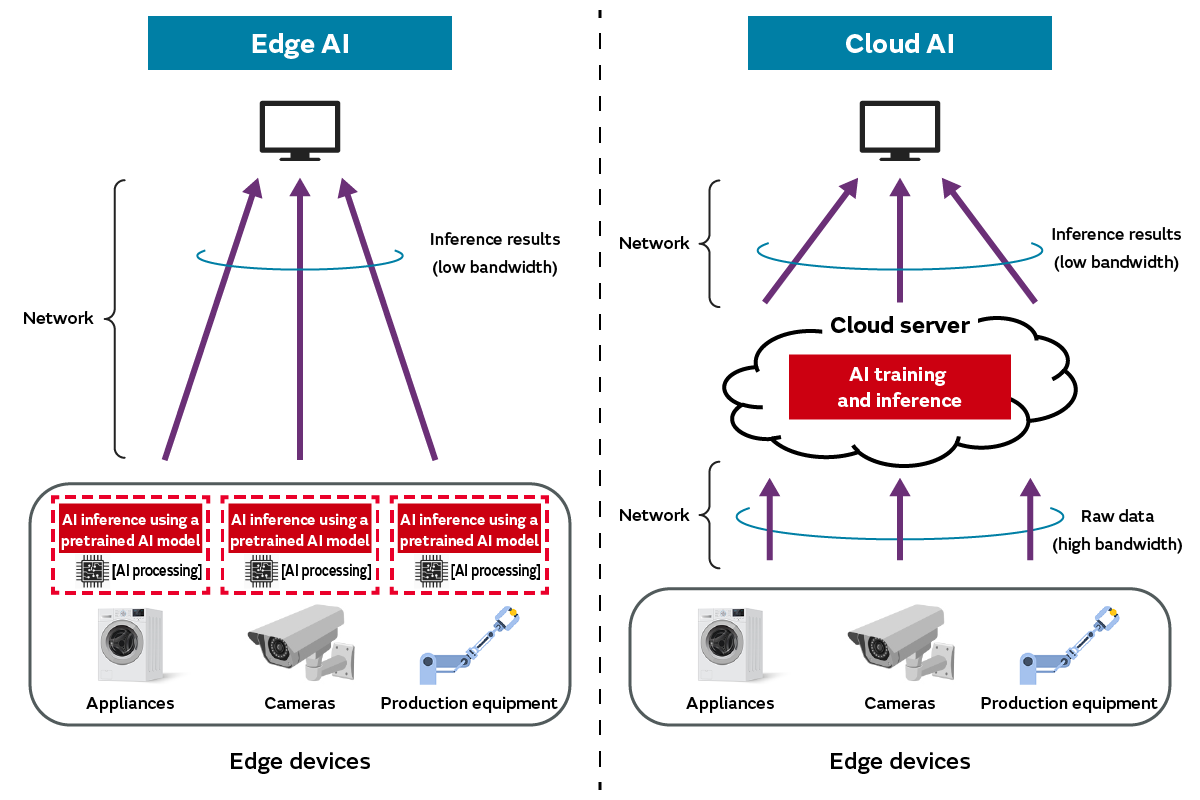

1. System Architecture

Key Components:

- CCTV Cameras:

- Installed at critical locations (entry points, work areas, warehouses, hallways).

- Continuously provide video data for analysis.

- Edge AI Devices:

- Hardware placed on-site (e.g., edge servers or AI-integrated IoT devices).

- Run machine learning models to analyze video from CCTV without needing to send data to the cloud.

- Factory Local Network:

- Connects CCTV and Edge AI for fast data transmission.

- Minimizes latency in processing.

- Central Management Software - MOJO AI VISION STUDIO :

- A management interface displaying notifications, reports, and live video streams.

- Can store data locally or integrate with cloud systems.

- Cloud Server (Optional):

- Stores data for long-term purposes and provides advanced analysis capabilities if needed.

- Synchronizes data with edge devices.

2. How It Works

Detailed Process:

- Data Collection:

- CCTV cameras capture real-time video.

- Video data is sent directly to Edge AI devices via the local network.

- Real-Time Analysis on Edge AI:

- Edge AI processes video data to:

- Detect safety violations (e.g., absence of helmets, reflective vests, or unauthorized entry into restricted areas).

- Identify abnormal behaviors (e.g., falls, collisions, or unsafe movements).

- Verify the correct usage of Personal Protective Equipment (PPE).

- Uses AI models such as YOLO, OpenPose, or advanced image recognition algorithms.

- Alerts and Actions:

- When a violation is detected, the system immediately triggers alerts:

- Alarms or warning lights on-site.

- Notifications via email, SMS, or management applications to the safety team.

- Logs incidents for later analysis.

- Storage and Reporting:

- Analysis results and video footage are stored in:

- Local memory on edge devices (short-term).

- Cloud servers (long-term, if needed).

- Generates periodic reports on safety compliance and incident frequency.

- Integration with Management Systems:

- The system connects to other platforms such as ERP or HSE (Health, Safety, Environment) systems to synchronize data and enhance management efficiency.

3. Model Diagram

- CCTV Cameras

↓ (Transmit video via the local network) - Edge AI Devices (Real-time analysis)

↓ - Alerts: Sent to on-site systems and CMS

↓ - Central Management System (Local or Cloud storage)

↔ (Integrates with other systems)

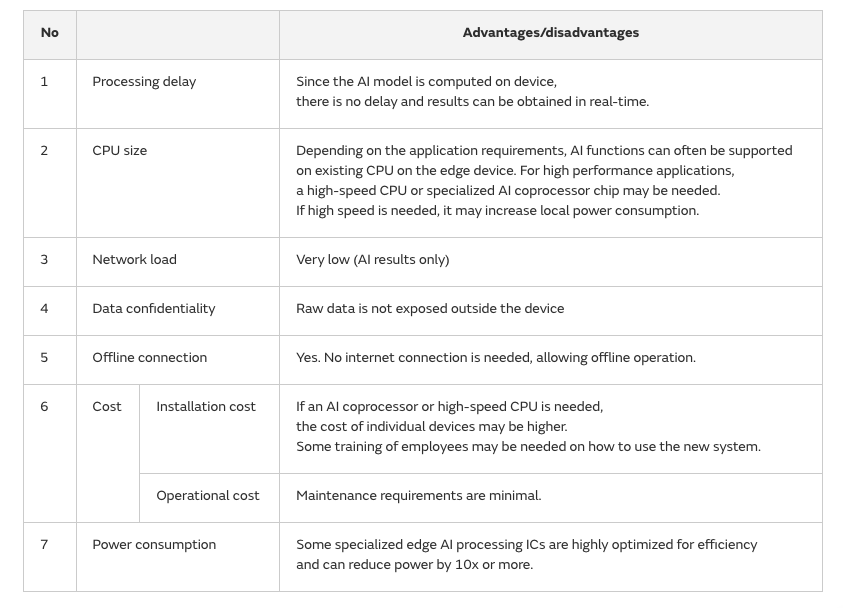

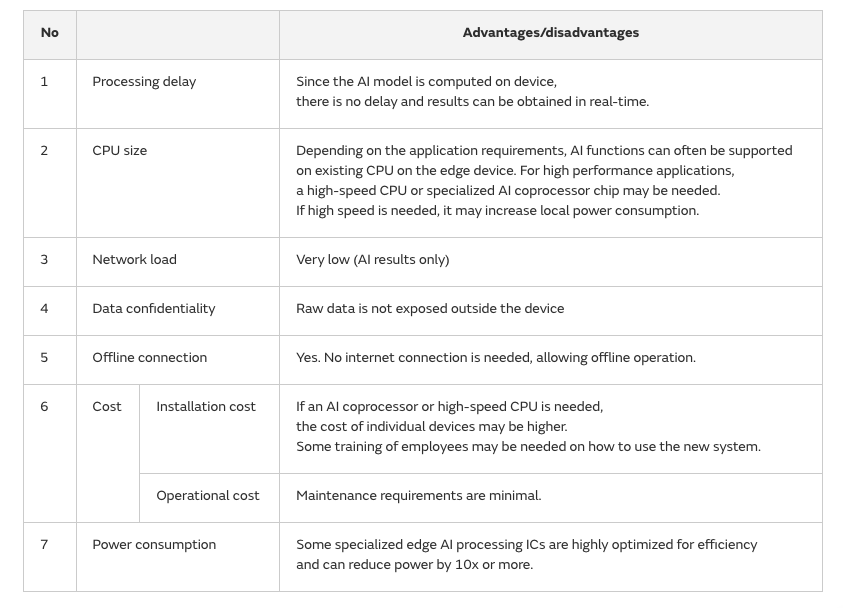

4. Advantages of the Model

- Quick Response:

- Processes data on-site, reducing latency compared to cloud-based systems.

- High Security:

- Data doesn’t need to be entirely sent to the cloud, reducing the risk of leaks.

- Optimized Bandwidth:

- Only sends critical information or alerts, saving network resources.

- Scalability:

- Easily add more cameras or edge devices if the factory expands.

- Lower Long-Term Costs:

- Reduces storage and processing fees on the cloud.

5. Specific Applications in Factories

- PPE Violation Detection:

- Checks if workers are wearing helmets, safety glasses, or reflective vests.

- Monitoring Hazardous Areas:

- Detects unauthorized entry into restricted or unsafe zones.

- Behavior Analysis:

- Identifies abnormal behaviors like slips, falls, or standing in unsafe positions.

- Headcount Management:

- Ensures the number of people in a workspace doesn’t exceed the limit.

6. Related Technologies

- AI Models: TensorFlow, OpenCV, PyTorch, Mojo AI Vision

- Edge AI Devices: Nvidia Jetson, Google Coral, Raspberry Pi

- Storage Systems: Hybrid Cloud (AWS, Azure) or on-premises systems.