Optimizes inspections with unique AI

Superior defect detection, item classification, optical character recognition

reduces inspection time and boosts accuracy compared to manual and less advanced systems, ensuring manufacturers meet high-quality standards.

Real-World Projects

Fish Counting in Sea

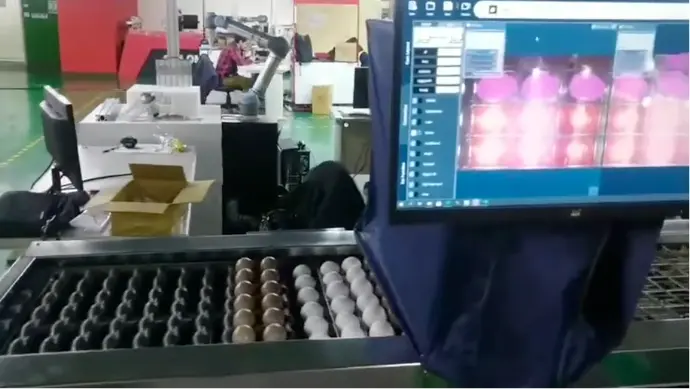

Conveyor Belt Packets Counting

Parking Management System

Object Counting in Regions

Quick learning

can train an AI model in minutes through Mojo Data Studio with unique model and various size of params

Diverse AI Vision

offers outstanding performance and versatility for a range of AI inspection applications, providing tailored automation solutions for specific industry needs.

Few Data

Can learn new items from as few as 1-5 image samples, saving users hours of exhaustive annotations..

Ideal for manufacturing, food & beverage, textiles, electronics

seamlessly integrates with several industrial cameras and includes built-in PLC communications via TCP/IP and Modbus protocols at no extra cost.

Defect Detection

Overcoming the limitations of ordinary defect inspection systems, Mojo Vision detects defects in real-time with speed and precision, ensuring greater inspection efficiency and higher standards of product quality.

Classification

With just a few sample images, our Data Studio uses advanced deep learning technology to quickly and accurately recognize and categorize different items much faster and with greater precision than traditional inspection methods.

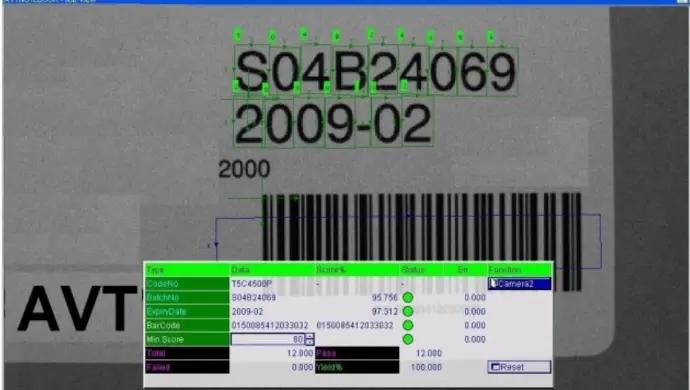

Understandable OCR with LLMs

Utilizes its built-in image processing capabilities to recognize numbers, characters, and text, seamlessly extracting this information into a digitized format with Large Language Model understandable.